No matter what the concern, a little TLC is always the first step and necessary if you want things to last and function at its full potential. This is why proper maintenance is key to lowering fuel usage and saving money.

When it comes to fuel consumption, you must look at the goals, which are operating at high efficiency to lower costs and having fewer breakdowns and repairs to provide an extended design life of your equipment. Staying on top of any/all adjustments as needed to restore system efficiency, will lower the fuel usage, and lower carbon emissions. A properly sized, clean, stable and efficient flame, should always be top priority. Of course most newer equipment is more efficient than older equipment, but even older equipment can be properly maintained to run at their peak efficiency as well.

Bottom line, details matter – especially when it comes to proper maintenance. Fewer breakdowns and the highest level of clean and efficient combustion will ultimately reduce fuel usage and be the most cost effective solution.

6 Steps to Lowering Fuel Usage

Homeowners are seeking opportunities to both maintain the safety and maximum cold-weather comfort in their homes, while reducing costs. Individuals now working from home are getting hit hard with the amount of money they are spending on utilities for both heating and cooling, and are running into different issues when it comes to maintenance and repair. The good news is that there are ways to lower fuel costs, and at the same time maintain the environmental advantages, safety, and comfort of Bioheat® fuel with effective maintenance.

Below is a case study of a homeowner who became a new customer of ours, with a two-family home, in Brooklyn, New York. Their modern boiler had an excellent Beckett burner that was operating inefficiently for quite some time, due to neglect and poor servicing. We took the most reliable steps to restore that Beckett burner to its maximum efficiency using our experience and the manufacturers specifications. This reduced their fuel consumption, saving them money and aggravation at the same time.

FLAME CHARACTERISTICS

It is important to understand the distinction between manufacturers theoretical fuel economy and real-world fuel consumption. Many people do not realize that the BTU input/size, and characteristics of the flame play a huge role in how much fuel is being burned up as you heat your home. Case studies reflecting a wide variety of boilers and warm air furnaces in homes and multi-unit apartments have run parallel in their discoveries. They have shown the “before” subject as being highly inefficient with smoking flames which produced wasteful carbon buildup and emissions, and unnecessarily high fuel usage. However, after installing the correct nozzle and making all the important adjustments to the fuel pressure, drawer assembly setting, and air-fuel mixture, the study indicated that the mechanics were able to control and maintain significantly better efficiency, economy, and clean combustion, while reducing breakdowns and emissions all do to the properly sized BTU input, and proper combustion to achieve the highest efficiency in each particular heating unit. Improvements in combustion efficiency are confirmed by using combustion analyzer equipment both before and after making the necessary corrections. Even a 5 or 10% increase in efficiency can save consumers hundreds of dollars a year!

It is important to understand the distinction between manufacturers theoretical fuel economy and real-world fuel consumption. Many people do not realize that the BTU input/size, and characteristics of the flame play a huge role in how much fuel is being burned up as you heat your home. Case studies reflecting a wide variety of boilers and warm air furnaces in homes and multi-unit apartments have run parallel in their discoveries. They have shown the “before” subject as being highly inefficient with smoking flames which produced wasteful carbon buildup and emissions, and unnecessarily high fuel usage. However, after installing the correct nozzle and making all the important adjustments to the fuel pressure, drawer assembly setting, and air-fuel mixture, the study indicated that the mechanics were able to control and maintain significantly better efficiency, economy, and clean combustion, while reducing breakdowns and emissions all do to the properly sized BTU input, and proper combustion to achieve the highest efficiency in each particular heating unit. Improvements in combustion efficiency are confirmed by using combustion analyzer equipment both before and after making the necessary corrections. Even a 5 or 10% increase in efficiency can save consumers hundreds of dollars a year!

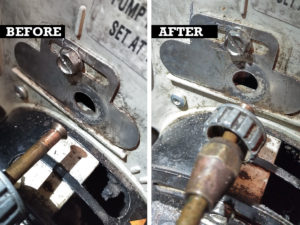

COMBUSTION HEAD

In the same case, the combustion head was carbonized due to the wrong “Z” setting of the drawer assembly, in addition to having the wrong fuel pressure, and the use of an incorrectly sized nozzle with the wrong spray pattern. This all led to poor overall combustion, low efficiency and significantly higher fuel costs. Since carbon buildup needs to be avoided, the combustion head was cleaned and the fuel pump pressure was set up based on the manufacturer’s specifications for proper operation.

In the same case, the combustion head was carbonized due to the wrong “Z” setting of the drawer assembly, in addition to having the wrong fuel pressure, and the use of an incorrectly sized nozzle with the wrong spray pattern. This all led to poor overall combustion, low efficiency and significantly higher fuel costs. Since carbon buildup needs to be avoided, the combustion head was cleaned and the fuel pump pressure was set up based on the manufacturer’s specifications for proper operation.

INSPECT AND ADJUST IGNITION ELECTRODES

When you have a Beckett drawer assembly that is positioned too far backward, combined with an incorrect nozzle and incorrect setting of the ignition electrodes, will lead to the same result of fuel loss and inefficiencies. The best thing to do is to reinstall with a new and correct atomizing nozzle, and then set the ignition electrodes back to their proper specs.

When you have a Beckett drawer assembly that is positioned too far backward, combined with an incorrect nozzle and incorrect setting of the ignition electrodes, will lead to the same result of fuel loss and inefficiencies. The best thing to do is to reinstall with a new and correct atomizing nozzle, and then set the ignition electrodes back to their proper specs.

SIDE PLATE

Another added component is the correct position of the drawer assembly and the side plate for the Beckett burner. in the above case, the plate was pulled too far backward due to the electrodes being set incorrectly, and because the wrong nozzle was used. All of these parts work together so when one is off, everything needs to be checked and reset in order to achieve the most efficient clean combustion for reduced fuel usage. The simple solution in this case was to adjust the side plate accordingly and to push it forward to the proper “Z” setting using a beckett gauge.

Another added component is the correct position of the drawer assembly and the side plate for the Beckett burner. in the above case, the plate was pulled too far backward due to the electrodes being set incorrectly, and because the wrong nozzle was used. All of these parts work together so when one is off, everything needs to be checked and reset in order to achieve the most efficient clean combustion for reduced fuel usage. The simple solution in this case was to adjust the side plate accordingly and to push it forward to the proper “Z” setting using a beckett gauge.

PRESSURE

At the beginning, the fuel pressure was found at only 85 PSI, which is much too low for good combustion. The correct fuel pressure on most equipment today needs to be set to at least 140 PSI. If the fuel pump pressure/psi does not meet manufacturers specifications, then a fuel pressure adjustment is essential.

At the beginning, the fuel pressure was found at only 85 PSI, which is much too low for good combustion. The correct fuel pressure on most equipment today needs to be set to at least 140 PSI. If the fuel pump pressure/psi does not meet manufacturers specifications, then a fuel pressure adjustment is essential.

NOZZLE

As mentioned above the incorrect nozzle needs to be removed. A new atomizing nozzle (1.10-80A) for this boiler was the solution. Using a nozzle that is too large or too small, with an incorrect spray angle or spray pattern for each specific burner or heating unit, will likely result in less than perfect combustion and higher fuel use.

The overall takeaway is that each part could not do its full potential if they all weren’t working together. If one thing is off, the rest will be off. Each one of those components needed to do its job for optimal fuel efficiency. When it comes to fuel efficiency this is no different when it comes to saving on gasoline for transportation. We cannot stress enough how important maintenance is when performed by professional technicians with experience in working with these types of equipment.

Cohler Fuel’s focus is always on superior service and expert repair in fuel efficiency

As licensed professionals leading the industry, our seasoned operators install new BioHeat® and oil heating equipment (boilers, burners, hot water and oil storage tanks) when needed due to failed equipment, or when needed to improve efficiency for lower fuel consumption. Only installing the most highly accredited and trusted name brands of equipment, with extended warranty coverage for our regular full-time fuel oil customers, Cohler Fuel will be able to provide the service and resources that you need.

Our service techs are NORA-certified and have years of experience in diagnosing and repairing heat, hot water, and combustion problems. Service is available 365 days a year, including holidays. Let Cohler help save you money. No headaches… Call 718-808-8833 today!